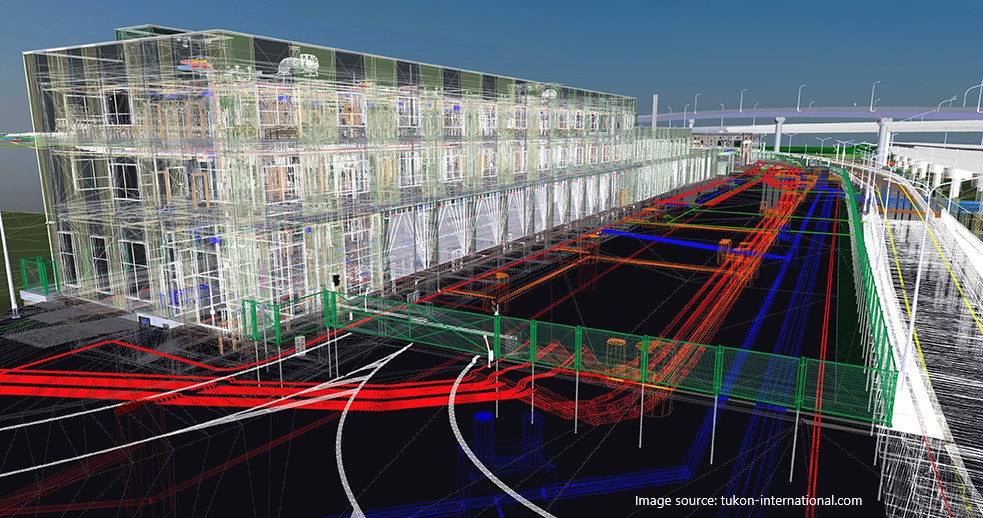

Ensuring safety on a construction site is a critical challenge for project managers. Construction environments are filled with hazards, from heavy machinery and materials to complex, multi-team operations happening simultaneously. Despite advances in protective gear, training, and regulations, accidents still occur, leading to injuries, delays, and increased costs. In this context, 4D planning is emerging as a transformative tool that enhances safety throughout the project lifecycle. By integrating time into traditional 3D Building Information Modeling (BIM), 4D planning allows for advanced visualization, simulation, and coordination, helping project teams anticipate and mitigate risks long before they manifest on-site.

Here’s why 4D planning is essential for the safety of your construction project.

- Proactive Hazard Identification

The most effective way to manage risks is to prevent them from happening in the first place. Traditional construction planning methods often rely on static 2D drawings or charts, which can make it difficult to foresee potential hazards until construction is underway. 4D planning, however, allows project teams to simulate each phase of construction, visualizing how the site will change over time and identifying risks well in advance.

With 4D planning, teams can anticipate safety challenges like:

- Confined spaces that require special precautions

- High-risk activities, such as crane operations or scaffolding erection

- Overlapping trades working in the same area, potentially leading to accidents

This proactive identification of risks enables managers to adjust the schedule, preventing dangerous overlaps and ensuring that tasks are executed safely.

- Safer Construction Sequencing

The sequence in which construction activities are carried out plays a crucial role in ensuring the safety of the site. A poorly planned sequence might lead to incomplete structural elements being exposed to external forces, creating dangerous conditions for workers. With 4D planning, project managers can carefully plan the construction sequence by simulating different scenarios and selecting the safest, most efficient path forward.

By optimizing the order in which tasks are performed, 4D planning minimizes the risk of accidents related to unstable structures, incomplete work areas, or the improper placement of equipment.

- Improved Site Coordination and Communication

Lack of coordination among different teams and trades is a major contributor to site accidents. Workers from various disciplines may inadvertently interfere with each other’s tasks, leading to confusion, overcrowding, or even equipment collisions. 4D planning facilitates better communication and coordination by providing a shared, time-based model of the construction process.

This model enables all stakeholders—from architects and engineers to contractors and safety officers—to see how their work impacts others and to plan accordingly. For example, if scaffolding is being erected in one area, 4D planning ensures that no other trade is scheduled to operate heavy machinery nearby during that time, significantly reducing the risk of accidents.

With improved coordination, everyone on the site knows what to expect, reducing misunderstandings that can lead to safety incidents.

- Efficient Resource Management and Site Logistics

On a construction site, materials, equipment, and workers need to move efficiently to avoid clutter and congestion, which can lead to accidents. 4D planning helps to optimize site logistics by visualizing how the project will evolve over time and determining the safest, most effective way to allocate resources at each stage.

This careful planning prevents dangerous situations, such as workers tripping over materials or heavy machinery obstructing safe paths. 4D planning ensures that site logistics evolve in tandem with the construction schedule, keeping the environment orderly and safe.

- Real-Time Adjustments for Safety

Construction projects are often subject to delays, unexpected changes, and unforeseen circumstances. When these occur, the original safety plans may no longer be relevant. Without a clear understanding of how schedule changes impact safety, construction sites can become dangerous very quickly.

With 4D planning, project managers can adjust schedules in real-time and immediately assess how changes impact site safety. This ability to update the construction sequence and resource allocation dynamically ensures that new hazards are addressed as they arise, keeping workers safe even when plans need to be modified.

- Enhanced Safety Training and Briefings

4D planning doesn’t just improve site safety during construction—it also enhances safety training and awareness. Before workers even arrive on-site, they can review 4D models to understand how the project will unfold and where the key hazards will be at each stage. This provides workers with a comprehensive view of their tasks in the context of the entire project, improving their situational awareness.

Furthermore, project managers can use 4D simulations in safety briefings to demonstrate real-life scenarios and explain specific risks and precautions in a visually engaging way. This helps workers grasp the critical importance of safety measures and better understand the potential dangers on-site.

By providing a dynamic, time-based model of the construction process, 4D planning allows project teams to anticipate risks, optimize construction sequencing, improve coordination, and adjust plans in real time. It not only enhances proactive hazard prevention but also fosters a culture of safety throughout the construction lifecycle. For any project aiming for high standards of safety, the use of 4D planning is not just a benefit—it’s becoming a necessity.

Draftech – Your Project, Our Expertise

Testimonials

Very professional and efficient organization. Delivered a great product to a tight deadline.

ACE Power

Karl and the team are very professional and have a vast knowledge of BIM coordination.

Dwayne Willaims Babinda Electrics

We had multiple large projects with tight deadlines and needed a company we could trust. The teams delivery, attention to detail and understanding of what is being designed is always executed to a high standard.

Martin O’Donovan Envar Engineers

Draftech offered a flexible and reliable approach to working collaboratively with our team. They met our expectations and quality requirements and also offered up new ideas.

Draftech have proven to be a valuable and trustworthy resource and we will continue to work with Draftech on other projects.

Simon Marsden Umow Lai

Draftech is different from others in the professionalism and features they provide.

The ability to walk through projects in real time online provides invaluable insight into problem areas and helps provide an efficient resolution on the spot without many phone calls, emails and the necessity for us to paw through countless drawings to understand the issues.

Todd Morris Manager - Air mech

Draftech were put forward to FIP Electrical as the solution to Coordinate, Model, carry out clash detection, provide Electrical Services Shop Drawings, as built documentation and completed electrical model.

Simon Thorpe FIP Electrical

In close collaboration Draftech set up all our systems and model deliverables. In this process Draftech have proven to be a valuable resource for us and demonstrated commitment, understanding and professionalism.

David Skelley DJCoalition

Draftech’s attention to detail and proactive nature throughout the project assisted us in identifying issues before becoming evident on site, saving us both time and unexpected costs.

Matt Payne PJM Engineering Services

They delivered very high quality Revit models and associated 2D documentation at key milestones, working to a tight budget and in strict accordance with the Architects’ BIM requirements.

Peter Thomas Geoff Hesford

We found Draftech’s work to be of high standard and the team delivered exactly as agreed, in fact, when we considered the project complete, Draftech put further resources into the project as they were not satisfied.

John Johnson Beca

Engaging Draftech during design gave us the tools to make smart decisions.

Hansen Yuncken Design Manager - Michael Harkins

The drafting service is timely, reliable and fit for purpose for the built environment.

Peter Harvey Harvey Industries

Draftech stands apart from other drafting services that we have previously used in their attention to detail and ability to adapt to the individual client’s requirements.

Doug Holt McCaig Aircon

I can confidently recommend Draftech as a solid and reliable supplier, and experts in their field. I look forward to working with them again in the near future.

Chris Behan Norman Disney & Young

After seeing the benefits Draftech provided us on the Townsville Hospital Redevelopment we have set up a relationship with Draftech and intend to continue to use their BIM knowledge and skills for our future projects.

Brad Lund Energy Power Systems

Draftech has no competition as they are in a class of their own.

John Boyes Babinda Electrics

Draftech Developments Drafting and Design Capabilities, in conjunction with their outstanding level of Client service and support has provided great solutions to our engineering and Drafting Design portions within our Gorgon Barrow Island Project.

Aaron Hazelton Applied Electro Systems Pty Ltd

Draftech set up necessary systems and workflows very quickly, but also setup auditable estimating and weekly cost tracking processes that we utilised, requiring little maintenance.

TOM PURDON MPM GROUP