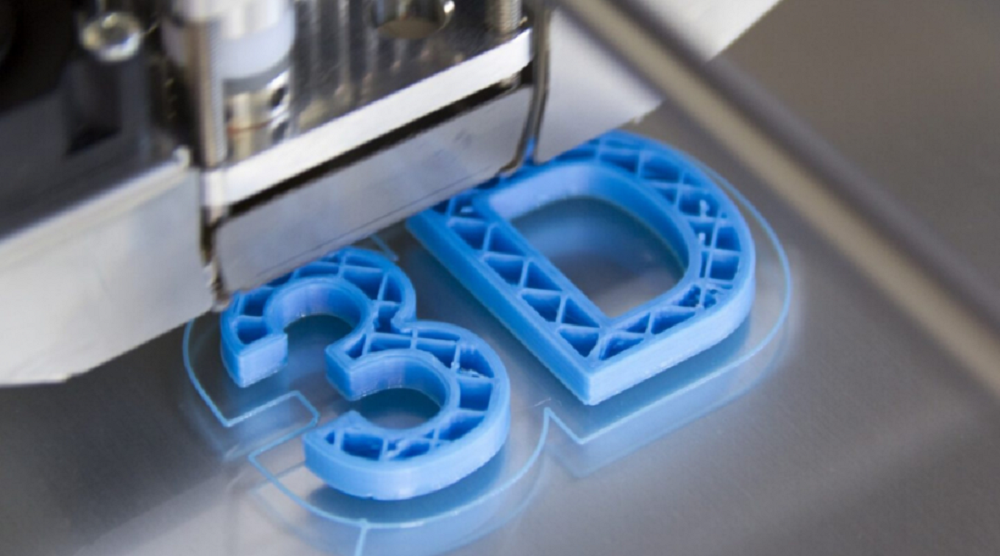

In the ever-evolving landscape of technology, 3D printing has emerged as a revolutionary force, reshaping the way we manufacture and conceptualize objects. As we step into the year 2024, the world of 3D printing continues to push boundaries, introducing innovations that were once thought to be the realm of science fiction. In this blog, we explore the state of 3D printing in 2024 and the transformative impact it has had on various industries.

Advanced Materials

One of the most significant developments in 3D printing technology is the expansion of materials used in the printing process. In 2024, 3D printers are not limited to traditional plastics; instead, they now accommodate an array of advanced materials, including metals, ceramics, and even biocompatible substances. This broadens the scope of applications, enabling the creation of intricate and durable objects suitable for industries such as aerospace, healthcare, and automotive.

Metal 3D printing, in particular, has gained traction, allowing for the production of complex metal parts with precision and efficiency. This has transformative implications for industries that require high-performance components, as 3D printing becomes an integral part of their manufacturing processes.

Speed and Efficiency

In 2024, 3D printing technology has undergone significant improvements in terms of speed and efficiency. Faster printing processes and enhanced layering techniques have drastically reduced the time it takes to produce complex objects. This increase in efficiency not only boosts productivity but also makes 3D printing more accessible for a wider range of applications.

In industries where time is of the essence, such as healthcare and prototyping, the swift turnaround of 3D printing provides a competitive advantage. Rapid prototyping allows designers to iterate quickly, accelerating the product development cycle. In healthcare, on-demand 3D printing of medical implants and prosthetics has become a game-changer, improving patient outcomes and reducing waiting times.

Customization and Personalization

One of the standout features of 3D printing is its ability to customize and personalize products on a mass scale. In 2024, this capability has reached new heights, impacting industries such as fashion, consumer goods, and healthcare.

In the fashion industry, designers leverage 3D printing to create personalized apparel and accessories tailored to individual preferences and body shapes. This shift towards on-demand, customized manufacturing reduces waste and aligns with sustainable practices.

In healthcare, 3D printing facilitates the production of personalized medical devices, such as implants and prosthetics, perfectly tailored to the patient’s anatomy. This not only improves the functionality of these devices but also enhances patient comfort and overall satisfaction.

As we navigate the terrain of 3D printing in 2024, it is evident that this technology has evolved beyond its initial capabilities, transforming industries and shaping the future of manufacturing. With advanced materials, increased speed and efficiency, and a focus on customization, 3D printing has become a versatile tool with applications ranging from aerospace to healthcare. As innovation continues to drive the field forward, we can only anticipate more groundbreaking developments on the horizon, further solidifying 3D printing’s place as a cornerstone of modern manufacturing.

Testimonials

Very professional and efficient organization. Delivered a great product to a tight deadline.

ACE Power

Karl and the team are very professional and have a vast knowledge of BIM coordination.

Dwayne Willaims Babinda Electrics

We had multiple large projects with tight deadlines and needed a company we could trust. The teams delivery, attention to detail and understanding of what is being designed is always executed to a high standard.

Martin O’Donovan Envar Engineers

Draftech offered a flexible and reliable approach to working collaboratively with our team. They met our expectations and quality requirements and also offered up new ideas.

Draftech have proven to be a valuable and trustworthy resource and we will continue to work with Draftech on other projects.

Simon Marsden Umow Lai

Draftech is different from others in the professionalism and features they provide.

The ability to walk through projects in real time online provides invaluable insight into problem areas and helps provide an efficient resolution on the spot without many phone calls, emails and the necessity for us to paw through countless drawings to understand the issues.

Todd Morris Manager - Air mech

Draftech were put forward to FIP Electrical as the solution to Coordinate, Model, carry out clash detection, provide Electrical Services Shop Drawings, as built documentation and completed electrical model.

Simon Thorpe FIP Electrical

In close collaboration Draftech set up all our systems and model deliverables. In this process Draftech have proven to be a valuable resource for us and demonstrated commitment, understanding and professionalism.

David Skelley DJCoalition

Draftech’s attention to detail and proactive nature throughout the project assisted us in identifying issues before becoming evident on site, saving us both time and unexpected costs.

Matt Payne PJM Engineering Services

They delivered very high quality Revit models and associated 2D documentation at key milestones, working to a tight budget and in strict accordance with the Architects’ BIM requirements.

Peter Thomas Geoff Hesford

We found Draftech’s work to be of high standard and the team delivered exactly as agreed, in fact, when we considered the project complete, Draftech put further resources into the project as they were not satisfied.

John Johnson Beca

Engaging Draftech during design gave us the tools to make smart decisions.

Hansen Yuncken Design Manager - Michael Harkins

The drafting service is timely, reliable and fit for purpose for the built environment.

Peter Harvey Harvey Industries

Draftech stands apart from other drafting services that we have previously used in their attention to detail and ability to adapt to the individual client’s requirements.

Doug Holt McCaig Aircon

I can confidently recommend Draftech as a solid and reliable supplier, and experts in their field. I look forward to working with them again in the near future.

Chris Behan Norman Disney & Young

After seeing the benefits Draftech provided us on the Townsville Hospital Redevelopment we have set up a relationship with Draftech and intend to continue to use their BIM knowledge and skills for our future projects.

Brad Lund Energy Power Systems

Draftech has no competition as they are in a class of their own.

John Boyes Babinda Electrics

Draftech Developments Drafting and Design Capabilities, in conjunction with their outstanding level of Client service and support has provided great solutions to our engineering and Drafting Design portions within our Gorgon Barrow Island Project.

Aaron Hazelton Applied Electro Systems Pty Ltd

Draftech set up necessary systems and workflows very quickly, but also setup auditable estimating and weekly cost tracking processes that we utilised, requiring little maintenance.

TOM PURDON MPM GROUP